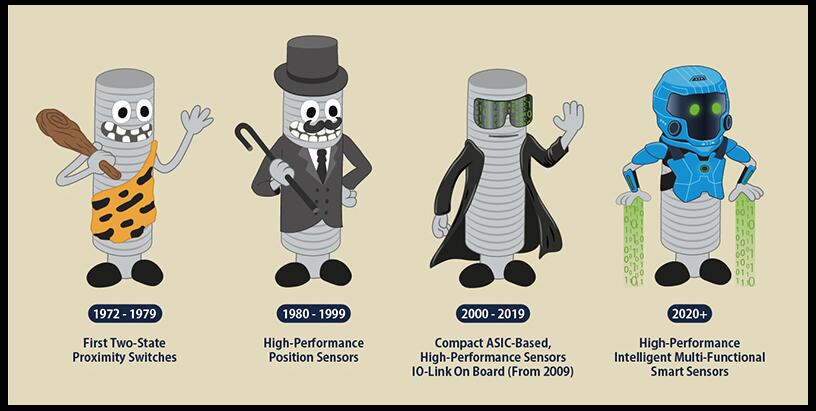

1972-1979 The first two-state proximity switches.

1980-1999 High performance position sensor.

2000-2019 Compact ASIC-based high-performance sensor with IO-link (since 2009).

2020+ high-performance multi-functional intelligent sensor.

From a one-man operation, it has now become an innovative global company with leading technology, operating 12 international subsidiaries, serving more than 60 countries and employing more than 500 people worldwide. As its first half century of development draws to a close, Contrinex reflects on its many achievements and achievements in the field of industrial automation.

The foundation of our commercial success has undoubtedly been the pioneering 3 and 4 times response range inductive sensor, which marked a major innovation in the market when it was introduced in the 1980s. This has allowed Contrinex to drive further technological innovation and enter into several commercial partnerships with other brands. The first miniaturized inductive sensor (diameter 3 mm) and its cousin (diameter 4 mm) were soon introduced. Both products are new to the world and highlight the company's innovative strength.

Contrinex has built on these two founding products to develop a range of high-performance inductive sensors, including many specialized models for harsh environments, such as our pioneering high-voltage, all-metal and anti-magnetic and anti-weld products. Over the years, we have developed equally versatile photoelectric sensor families, strengthening the overall strength of our product portfolio.

My father was definitely a digital pioneer, and he decided in the late 1990s to throw himself "full time" into digitizing our products by developing our first ASIC chip (application-specific integrated circuit) for standard inductive sensors. It's a bold move for Contrinex because of the technical risk. The project was a success and allowed us to move forward with a scalable, efficient technology platform.

Since then, we have built on this success by designing new ASics for different product groups. From the outset, we have been able to integrate IO-link on the ASIC platform, and since 2009, this has enabled us to provide a digital data output at no additional cost. Adding IO-link brings a whole new set of capabilities to the product and is the first step in integrating advanced logic into the sensor. The ability to set alerts is moving the industry toward using rudimentary process sensors alongside diagnostic tools to enable the smooth operation of machines or automated units.

We have designed our smart sensor family on top of these mature platforms, which we believe is the culmination of sensor technology as we know it today.

These versatile, multi-mode smart devices are changing the way people think about ordinary location sensors, adding value in areas such as predictive maintenance, production monitoring and process control.

Not only do smart sensors provide the same routine process data as conventional devices, they also report outlier-based events, including deviations from sensing targets, ultra-mild and other anomalies. Smart sensors benefit from dual-channel communication, for example, being able to initiate an emergency shutdown in the event of an imminent failure.